- Fast Charger Resources

- At a glance

- System History & Development

- Technical Specifications

- 448 Charger Brochure

- Fast Charger Brochure

Click the links on the left to learn more about how to increase your bottom line by adopting our state of the art fast charging technology

Adopting our future-oriented fast charger yields several rewards. Cut operation, maintenance and hardware costs, increase the flexibility of your man hours, reduce your carbon emissions and lower your bottom line.

Contact a rep today to find out more about how to integrate.

At a Glance

A Hollistic Overview of our Fast Charger Systems & Key Advantages

Key Advantages

Eliminate battery changes |

|

Maintenance costs savings |

|

One Fast Charger replaces 4-10 conventional chargers for electrical savings |

|

Chargers are strategically placed throughout the facility |

|

Reduce truck traffic near battery change room |

|

Reduce Watering Requirement |

|

Increased operator and truck availability and productivity |

Figure 1: Visualization Of The Fast Charger Current Distribution

Traditional Operation |

Fast Charger System |

|

|---|---|---|

Minimum 1 battery per shift, per truck |

→ |

One battery per truck, TOTAL! |

Battery depletes in, 5-8 hours, chargers 6-8 hours and rests 3-8 hours |

→ |

Battery charger when required, at operator breaks and lunch times - is not depleted |

Charging occurs in Battery Room |

→ |

Charging occurs on-board in convenient facility locations |

One battery charger lift truck |

→ |

One battery charger per multiple lift trucks |

Battery change out euipment required |

→ |

No change out equipment required |

System History & Development

L & H Power Group Inc is the world leader within emerging technologies for rapid charging batteries. Our specialization lays within rapid electrical vehicle charging technology.

L & H Power Group Inc is the world leader in developing technology for rapid charging batteries with their invention of the Fast Charger rapid charging technology.

The 448/335 rapid electric charging station has recharged several types of batteries in as quick as 10 to 30 minutes without overheating or damaging them, a feat that other charger manufacturers have failed to accomplish.

There are 3 main features:

-

1. It charges quickly

2. IT charges safely

3. It extends the battery's life

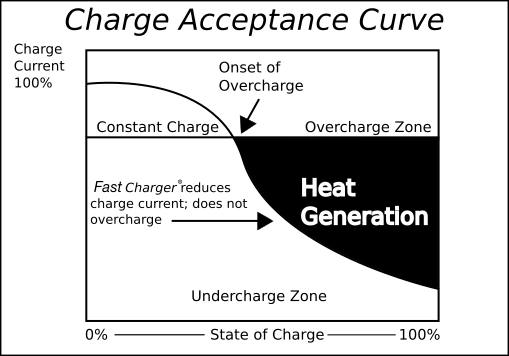

The Fast Charger doesn't only charge fast, its system utilizes the same diagnostics for slow charging which gives a safe charge while also extending the battery's life.

All Fast Chargers have an intelligent subsystem whereby they cintinually adjust the charge current to match the battery's charge acceptance ability. This enables the fastest possible charge, miniizes energy requirements and improves the battery's life.

In a recent successful test, it was demonstrated that one of the more advanced battery electrochemstries (Nick Meta Hydride) has resulted in attaining 4000 charge and discharge cycles. A lifecycle of 4000 cycles equates to 10 years in the life of a forklift. This is significant because the cost of a battery pack of 4000 cycles over the present 1000 cycles, the cost of the pack is reduced by a factor of 4.

Technical Specification

Figure 1.1: Typical Model 448/355 Charger Position

1.1 System Power-up

The following describes selection and auto-start of connected vehicles upon power-up or in the event of a system reset.1.1.1 Power-up With No Vehicles Connected:

Upon Power-ON the system with no vehicles connected will perform the following:- Site-Controller display indicates no vehicles are connected after initialization

- Each of the Remote displays indicate the appropriate station number during initialization

- Remotes detect that no vehicles are connected after initialization

1.1.2 Vehicle Connect after Power-up

When a vehicle is connected to a Remote Station it is not detected until the Start button is pressed. The following is observed:- Remote display indicates no vehicle is connected (continues to read “Connect Vehicle Press Start”)

- Site-Controller display indicates no vehicles are connected Press the Start button on the Remote station and observe the following:

- Remote display indicates a vehicle is connected and, after some time, it becomes selected for charging

- Site-Controller display indicates a vehicle is connected and charging at the appropriate station

1.1.2 Power-up With One Vehicle Connected (Auto-Start)

Upon Power-ON the system with one vehicle connected will perform the following:- Site-Controller display indicates the appropriate vehicle is connected after initialization

- The appropriate Remote detects that a vehicle is connected after initialization

- Charging commences at the appropriate Remote station after initialization

1.2 Charge Sequencing

Charge Sequencing consists primarily of two functions: (1) determining when to sequence and (2) determining which vehicle to sequence to. Charging and sequencing occurs in intervals delineated by five SOC ranges: below 80%, 80-89%, 90-99%, 100% and equalized. Below 80% SOC, vehicles are charged in multiples of 8-minutes. Sequencing also occurs, charge priority is evaluated among connected vehicles. The vehicle deemed to have the highest priority becomes selected for charging. The primary factor in selecting one vehicle over another is the vehicles’ state of charge (SOC) - - the lower the state of charge, the higher the priority. Secondary factors are the number of charge-discharge cycles since the last full charge and the last equalization – the higher the values, the higher the priority in requiring a full charge or equalize.

1.2.1 Single Vehicle Charging

When only one vehicle is charging on the system, charging should be continuous and uninterrupted until it is equalized.

When the Start button is pressed on the Remote station the following is performed:

- Charging commences for vehicle

- Charging continues uninterrupted over multiple 8-minute intervals

- When vehicles reaches 80% SOC, charging continues uninterrupted

- When vehicle reaches 90% SOC, charging continues uninterrupted

- When vehicle reaches 100% SOC, charging continues uninterrupted

- When vehicle is equalized charging is stopped and Remote Station displays "Charge Complete"

1.2.2 Equalized Vehicles

Vehicles that remain connected to the system after they have been equalized do not participate in the charge sequencing process.

1.2.3 Multi-Vehicle Charging

The following describes the sequencing that takes place at each SOC range boundaries and at the eight minute intervals when charging below 80% SOC. The following are vehicle-sequencing criteria that are described in this section:

- Below 80% SOC: select lowest SOC

- 80-89% SOC: select highest “Cycles Since Last Full Charge” (CYCSLF)

- 90-99% SOC: select highest “Cycle Since Last Full Charge” (CYCSLF)

- 100% SOC: select highest “Cycles Since Last Equalized” (CYCSLE)

- two or more vehicles have same CYCSLF, or CYCSLE: select lower SOC

- two or more vehicles have same SOC: select lower numbered station

- newly selected vehicle is already charging: continue to charge until the next evaluation

- newly selected vehicle is in stand-by: sequence to that vehicle

1.2.3.1 Sequencing at Less Than 80% SOC

When charging multiple vehicles at less than 80% SOC, the system re-evaluates which vehicle has the lowest SOC every eight minutes. If at this time, the vehicle currently charging still has the lowest SOC, it continues to charge without shopping. If the current vehicle’s SOC is greater than another’s charging is sequenced to the other vehicle. If two or more SOC’s are equal, charging is sequenced to or continues at the lowest-numbered station. All other vehicles with 80% SOC or greater remain on stand-by.

1.2.3.3 Sequencing at 90% SOC

When charging reaches 80% SOC, charging is sequenced to another vehicle under two conditions: (1) another vehicle is in stand-by at 80-89% SOC, and (2) another vehicle is at 90-99% SOC and has a higher “Cycles Since Last Full Charge” value. If for condition 2, the “Cycles Since Last Full Charge” values are the same for two or more vehicles, the vehicle with the lower SOC has higher priority. Further, if CYCSLF’s and SOC’s are equal, the lower numbered Remote Station has higher priority. All other vehicles remain on stand-by.

1.2.4 Sequencing at 100% SOC

When charging reaches 100% SOC, charging is sequenced to another vehicles under two conditions: (1) another vehicle is in stand-by at 90-99% SOC, and (2) another vehicle is at 100% SOC and has a higher “Cycles Since Last Equalize” value. If for condition 2, the “Cycles Since Last Equalize” values are the same for two or more vehicles, the lower numbered Remote Station has higher priority. All other vehicles remain on stand-by.

1.2.5 Sequencing When Equalized

When equalization is reached, charging stops. If an unequaled 100% SOC vehicle is connected, charging is sequenced to that vehicle.

1.2.6 Charge Interruption

Charge interruption is when charging is stopped for a vehicle before a regular sequencing boundary is reached. There are essentially two ways to interrupt a charge: by connecting another vehicle with a higher priority or by a user stopping and disconnecting the charging vehicle. This section only deals with the former. Charge stop and vehicle disconnect are described in section 1.2.5. Charge preemption by a connecting vehicle is conditional on the states of the charging and connecting vehicles. As a general rule, a charge can be preempted only by a vehicle with an SOC range below that of the charging vehicle. A connected and equalized vehicle does not participate in charge sequencing.

1.2.7 Interrupt Charging of Below 80% SOC

When a vehicle at less than 80% SOC is charging, it cannot be immediately preempted. Charging may be sequenced to a vehicle connecting at a lower SOC after the eight-minute charge interval.

1.2.8 Interrupt Charging of 80-89% SOC

When a vehicle at 80% to 89% SOC is charging, it can be preempted only by a vehicle connecting with less than 80% SOC. It can not be preempted by a vehicle connecting in the same SOC range, even if it has a lower SOC or higher “Cycle Since Last Full Charge” value. Rather, sequencing will take place only when the charging vehicle reaches 90%.

1.2.9 Interrupt Charging of 90-99% SOC

When a vehicle at 90% to 99% SOC is charging, it can be preempted only by a vehicle connecting with less than 90% SOC. It can not be preempted by a vehicle connected in the same SOC range, even if it has a lower SOC or higher “Cycle Since Last Full Charge” value. Rather, sequencing will take place only when the charging vehicle reaches 100%.

1.2.10 Interrupt Equalizing of 100% SOC

When a vehicle at 100% SOC is equalizing, it can be preempted only by a vehicle connecting with less than 100% SOC. It can not be preempted by a vehicle connecting in the same SOC range, even if it has a higher “Cycle Since Last Full Charge” value. Rather, sequencing will take place only when it is equalized.

1.2.11 Stop And Disconnect

A vehicle can be disconnected from the system under three possible conditions: (1) while it is charging, (2) while it is in stand-by awaiting charge, and (3) after it has been equalized. For cases 1 and 2, a vehicle should be disconnected only after the Stop button on the Remote Station has been pushed. However, as a safety measure, the system is designated to handle a vehicle disconnection without the Stop button being pressed. When this happens while a vehicle is charging, this feature is known as Fast-Shutdown.

1.2.12 Stopping Charge

Pressing the Stop button while charging (as mentioned in section 1.2.4) is one of two causes of charge interruption. Like charge interruptions via vehicle connect, sequencing takes place at this juncture. Determination of priority and vehicle selection are identical to those already described above. This section only describes the stop and disconnects functionality and that sequencing takes place thereafter.

1.2.13 Pressing Stop While Charging

Pressing the Stop button on a Remote Station for the Vehicle – 1 that is charging the following is observed:

-

(a) Charging immediately stops on vehicle-1.

(b) Charging is sequenced to other vehicles.

(c) Site-Controller continues to recognize vehicle-1 as connected (but stopped)

1.2.14 Pressing Start While Stopped

Restarting a vehicle that was stopped but not disconnected is the same as connecting and starting, in terms of sequencing. However, one fundamental difference between restarting and connecting is that for the former, Amp-hours and other charge cycle data are retained.

1.2.15 Fast Shutdown

Fast-shutdown occurs when a vehicle is charging, but gets connected without previously pressing the Stop button. The fast-shutdown feature is intended to disrupt current flow and prevent arcing in the event that charge connectors are inadvertently disengaged while charging.

Disconnect vehicle – 1 without pressing Stop and the following is observed:

-

(d) Charging stops on vehicle – 1 (within 30 milliseconds)

(e) Charging is sequenced to other vehicles

(f) Site-Controller indicates vehicle – 1 is disconnected

1.2.16 Disconnect After Equalized

After a vehicle has been equalized, it no longer participates in the charge sequencing. Disconnecting an equalized vehicle has no effect on charging and stand-by vehicles.

1.2.17 Stop & Disconnect From Stand-by

Shopping and disconnecting a vehicle while it is in stand-by removes that vehicle from the sequencing process. It has no effect on the remaining vehicles.

1.3 Conditions Preventing Vehicle Selection

1.3.1 Temperature Out of Range

1.3.2 Voltage Out of Range

1.4 Tools Required for Servicing

1.4.1 Meters

Digital Multimeter (with AC Volts-0 to 750, DC Volts 0 to 100, ohms Scales) Current Clamp Meter (0 to XXXX DC, 0 to XXXX AC)

1.4.2 Hand Tools

-

Phillips Screwdriver (#2)

Slotted Screwdriver (1/4” and 1/8”)

Wire Strippers (16 AWG to 26 AWG)(CLAUSS WS-6)

Needle Nose Pilers (XCELITE 378M)

Wire Side Cutters (XCELITE 170M)

Flashlight

Socket Set (1/2” Drive various size sockets)

Wrenches (Various size Open/Box End)

1.4.3 Programming Tools

Computer Systems with Windows NT (or 95/98) operation system

Programming Cables

1.4.4 Software Tools

BICC

Site/Digital Remote Controllers